Week 17 Applications and Implication

Objectives for Week 17

- Answer a questionnaire regarding the final project

What will it do

It will be an interactive and fun lighting design. Could be used as a playful insatllation

or as an aesthetic addition to houses.

Who’s done what beforehand

The design was inspired by bloom a lighting lamp. Find more details about it here

What will you design

The original design is more manual in the sense it blooms when a knob is rotated manually. I wanted to automate but adding an interface which will control it’s movement

What processes will you use

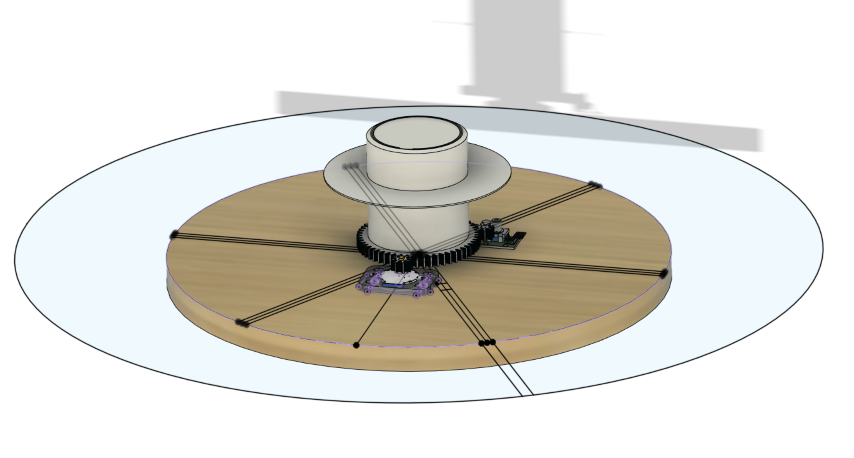

- CNC: Plywood Base

- Laser cutting: Acrylic frame for led

- 3D printing: Pulley, stopper

- Cutting and creasing in Zund: Upper fabric leaf

- PCB milling: Contoller board

What materials and components will be used?

Where will they come from?

I got almost all of my materials from the lab inventory except for the sheet which I bought from a nearby stationery shop

How much will they cost?

The total cost is roughly 3000INR

What parts and systems will be made?

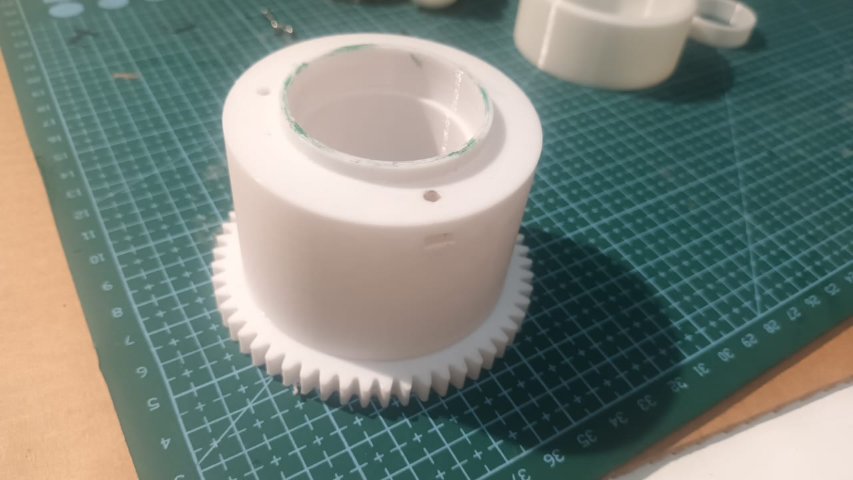

Gears, knobs, base were be made in the lab

How will it be evaluated?

It will be evaluated based on how smooth the movement of the leaf is. The change in light intensity.

Project Development

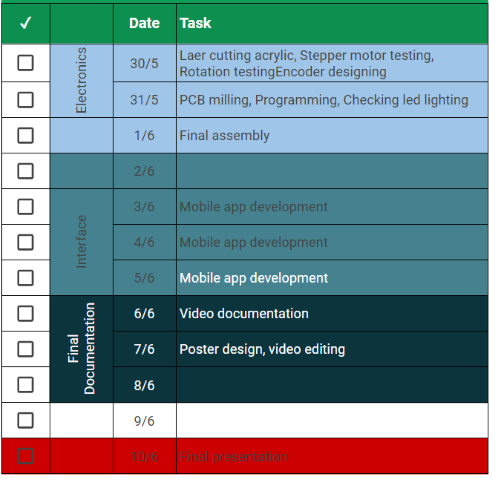

Completed tasks Vs Remaining tasks

| Completed task | Remaining tasks |

|---|---|

| CNC plywood base | Laser cutting acrylic strips |

| Finalised bloom pattern | Finalising design of button |

| 3D printed shafts | Finding a material for the bloom pattern |

| 3D printed clamps | 3D printing buttons |

| Laser cut acrylic strip sample | Designing a platform to mount Neo pixel |

| PCB design/programming Stepper motor | |

| PCB design/ programming encoder | |

What’s working what’s not

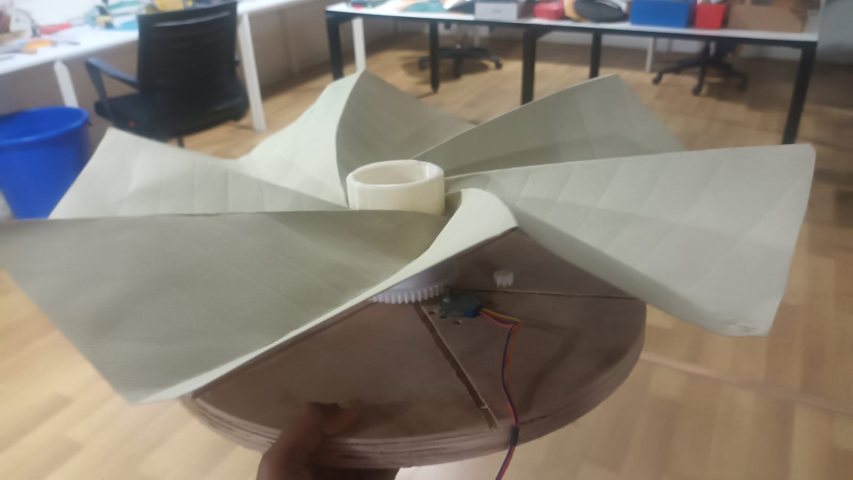

The blooming pattern is working. The mechanism seems to be fine I haven’t been able to finalise the design of the snap-fit button.

What will happen/ when

What have you learned

I have understood the process of designing a simple machine. Atleast I can recognise few mechanisms and identify what electric component will facilitate them.

Evolution of design

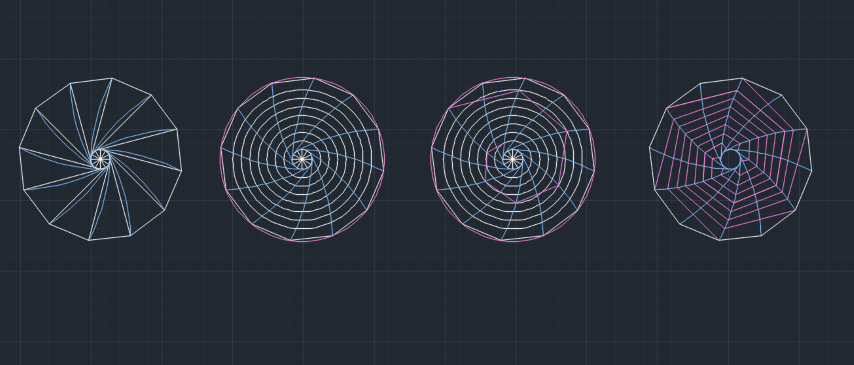

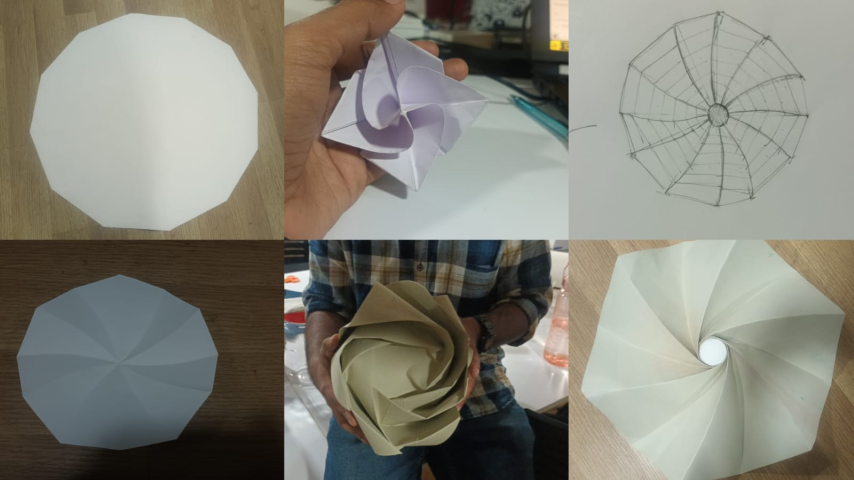

- Design of leaf pattern

The design was shown in the video I referred to but I still I had to figure out the pattern which enables proper movement

I tried cutting the pattern of with slight changes in dimension. As of now the pattern works in a chart paper. I have to figure out what material I can actually use.

Factors to be considered while choosing the material

- Has to be stiff enough to maintain the shape after creasing

- Should let light pass through it

- Should’nt tear or wrinkle after using multiple times

CNC cutting base

To see if the design actualy works, it was important to cut the base so that the other part can be assembled on it. So I decided cut the base as soon as I finalised the pattern

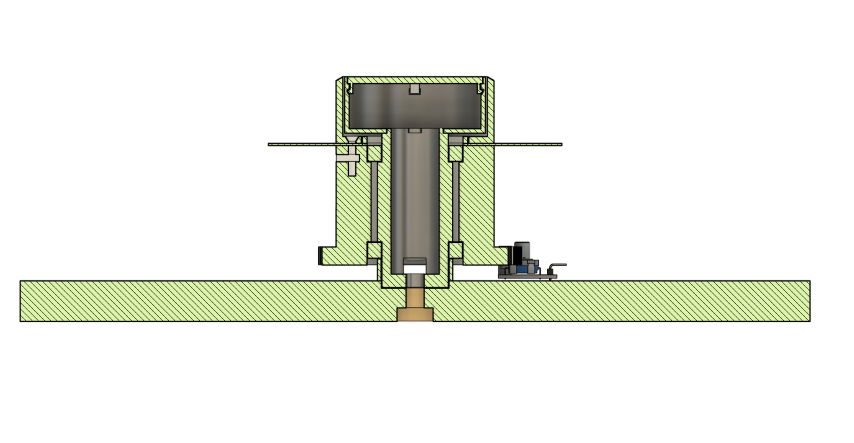

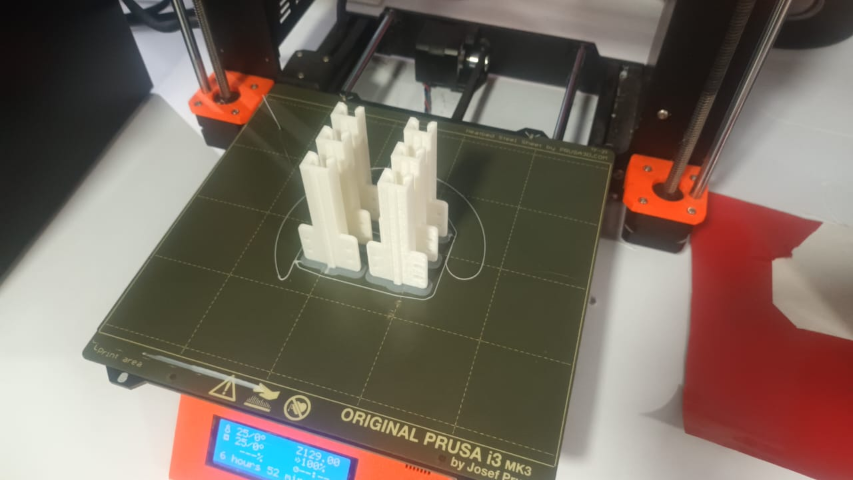

3D printing parts

I have finished 3D printeing almost all the required parts. Mainly shafts, clamps, gears

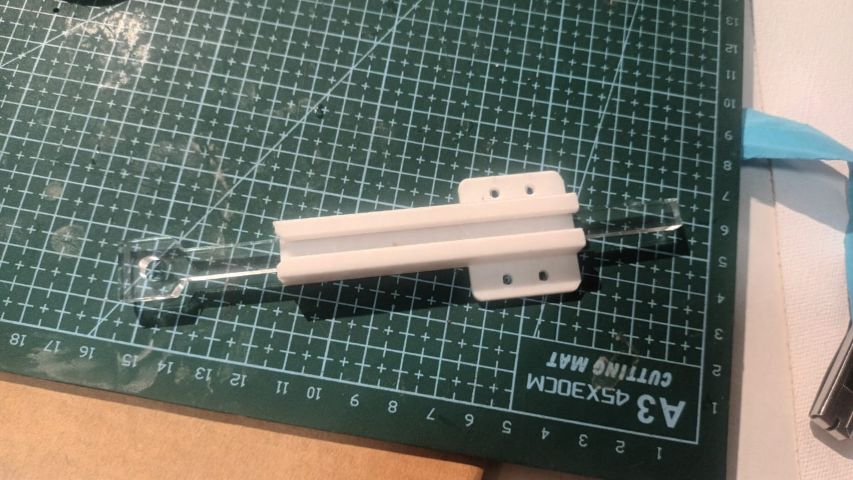

Lase cutting acrylic rod

The design I refered actually used a MS rod but I decided to use acrylic board instead. I was also doubtful about the length of the rod until I finalised the pattern. The length of rod controls how much the pattern can actually bloom

Progress as of now